Top 5 WRONG things most engineers often do when look for gear motor for their products.

When engineers need find their new design or product suitable gear motors, some may make the typical mistakes easily as below :1st mistake : The higher the torque is , the better the gear motor is .

If the motor is too powerful , it would not only increase your budget greatly , but also destroy your mechanism, plus it would draw higher current , resulting in extra power consumption. For some battery operated application product, low current is vital .

2nd mistake: Look for gear motors per power(output power or input power) .

Voltage /speed /torque are 3 necessary parameter to finalize a motor‘s performance , NOT the power . The mechanical engineer or electrical engineer should calculate the speed and the torque that their product need per their design. The speed and the torque decide the power. You may refer to the following formula: Output power=Load speed x rated torque /9550 ( P = T * n / 9550). So we get to know the power from the speed and torque .

3rd mistake: Source gear motors without torque data .

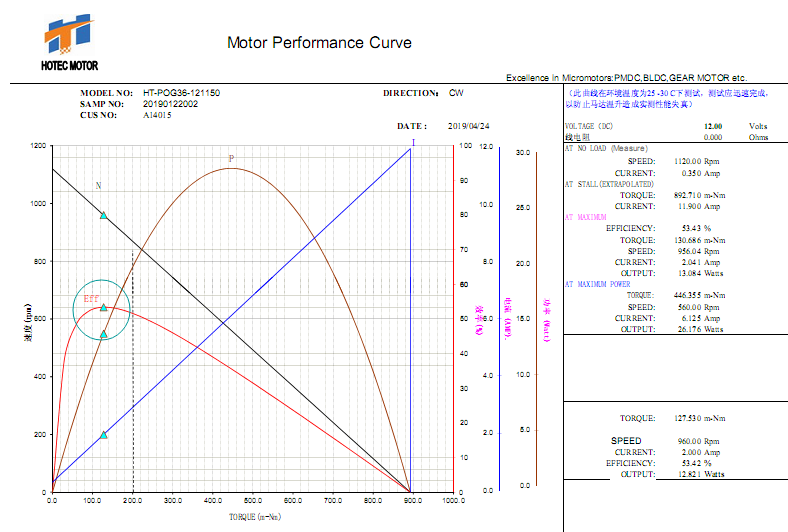

To facilitate your understanding , pls refer to the following Performance Curve of HT-POG36 12V Planetary gear motors .We can see the certain speed is based on some torque . If wrong torque , consequently the motor can‘t output your desired speed , even get damaged in your application .

To maximum make use of the motor and longer lifetime,the rated speed and rated torque we define would be at or nearby the max efficient point as showed in the curve .

4th mistake: Regard DC gear motor as standard products and want stock and price directly .

There are ineed a few gear motor suppliers or manufacturers on the market to supply stanard DC gear motors, like online retailor Pololu. But for commercial purpose ,especially when mass production , this is not the ideal,even good solution . DC gear motors are a combination of DC motor and gearbox. Its config and materials depend on customers‘ specifications and applications, including the gear ratio, gear materials, brush ,windings .

Different gear ratio have different quantity of gears , the cost would be different . Take HT-SOG12c for example (N20 gear motor), the cost variance between 10:1 gear ratio and 1000:1 are up to 1 USD.

Gear materials: gears can be made of 45#steel, free-machined steel, Sintered metal and plastic. Our engineers would make evauation per the motor‘s working condition in your application and decide the materials and make you samples to test . Stronger gears would be used in scenario where the torque is at high side, or motors may stall, or motors would reverse suddenly .

Obviously the cost are different ,and price is not available until gear motors pass your test and the solution is finalized . To help customers with budget check ,usually we will estimate a price range for customer‘s reference .

5th Mistake : Use 24VDC gear motors at 12V or use 12VDC gear motors at 24V.

Operation this way will result in carbon power deposit and burnt varistors, and do harm to gear motor‘s lifetime. Materials of the brushes are different according to motor‘s specifications and usage. Therefore, if you want 12V 3000 RPM DC motors, DO NOT use 24V 6000 RPM DC motor at 12V to get it .